|

Search

|

|

only one

keyword search term per box

|

|

| |

|

Categories

|

|

|

|

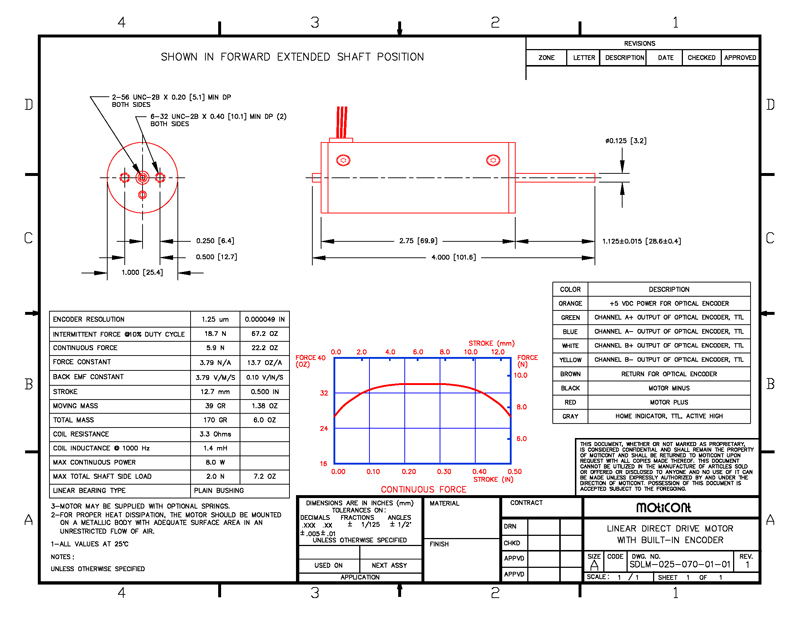

Electric Cylinder with Built-in Position Sensor

item #: ELCY-025-070-01-05

Availability: Will ship within one week.

Electric Cylinder with Built-in Encoder

Diameter: 1.00" (25.4 mm), Length: 2.75" (69.9 mm) L

Encoder Resolution: 5.00 um

|

|

|

| Unit Price: |

|

|

|

| 1-4 pieces: |

$1,120.40 |

|

|

| 5-9 pieces: |

$969.88 |

|

|

| 10-24 pieces: |

$859.02 |

|

|

| 25-49 pieces: |

$859.02 |

|

|

| 50-99 pieces: |

$859.02 |

|

|

| Prices for larger quantities may be obtained by contacting us or by clicking the RFQ below. |

|

|

| OEM quantities, more than 100 units or special instructions: |

|

|

|

|